-

How to improve design flexibility of toolbox molds

2025-11-17Toolbox molds are commonly used to produce toolboxes with complex structures such as multiple chambers and buckles, in order to improve their design flexibility. The core is to adapt the mold to the production of toolboxes of different specifications, facilitate rapid iterative optimization, and reduce transformation costs. This can be achieved through modular and parametric design, the use of int

-

How to demonstrate the impact resistance of plastic toolboxes

2025-11-10The impact resistance of plastic toolboxes is mainly reflected through structural design, material properties, and practical performance. The core is to withstand external impact without breaking or deforming, and to protect the internal tools. 1. Core embodiment dimensions The impact resistance of the material itself: Mainstream engineering plastics such as ABS, PP, HDPE, etc. are used,

-

What are the key design points of toolbox molds

2025-11-03The key design points of toolbox molds revolve around product accuracy, production efficiency, and molding quality, with five core dimensions. 1. Design of cavity and structure Correctly match the size, wall thickness, and appearance contour of the toolbox, and reserve reasonable shrinkage allowance.

-

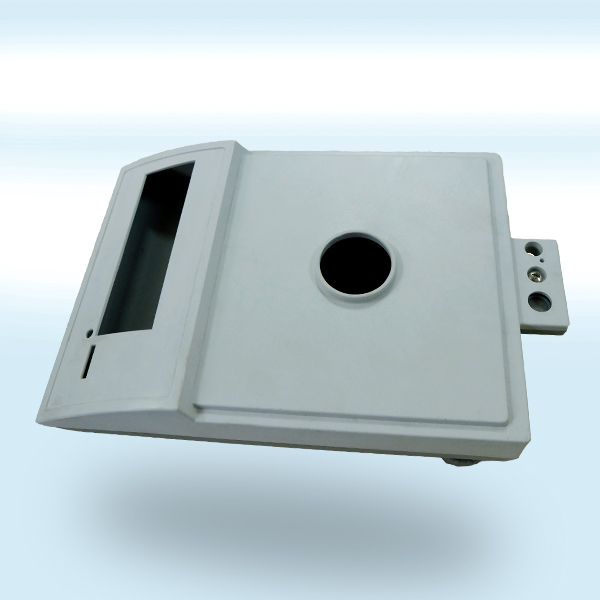

How to choose suitable electronic scale mold materials

2025-10-27The core of selecting electronic scale mold materials is to match product requirements, mold lifespan, and cost budget, taking into account the material, accuracy requirements, and production batch of electronic scale components.

-

Why do outdoor assignments require plastic toolboxes

2025-10-20The core of choosing a plastic toolbox for outdoor work is its ability to address the three major pain points of waterproofing, weather resistance, and portability in outdoor environments, providing reliable protection for tools and improving work efficiency.

-

What types of toolbox molds can be classified according to different materials

2025-10-13Toolbox molds can be divided into two categories based on their materials: plastic toolbox molds and metal toolbox molds. The design logic, applicable scenarios, and processing techniques of the two types of molds differ significantly. The specific classification and characteristics are as follows:

-

Where is the quality control of electronic scale molds reflected

2025-10-09The quality of electronic scale molds directly determines the accuracy, stability, and service life of core components such as the electronic scale shell, tray, and sensor mounting base. Its quality control needs to run through the entire process of "design processing trial mold mass production", focusing on five dimensions: dimensional accuracy, structural stability, material adaptability, surfac

-

Why do many people like to use plastic storage boxes

2025-09-29Many people like to use plastic storage boxes because they balance practicality, economy, and convenience, and can efficiently meet the needs of various storage scenarios. 1. Strong practicality and adaptability to multiple scenarios The structure and performance design of plastic storage boxes enable them to meet the storage needs of different environments.

Home

Home

Product

Product

Wechat

Wechat

Telephone

Telephone